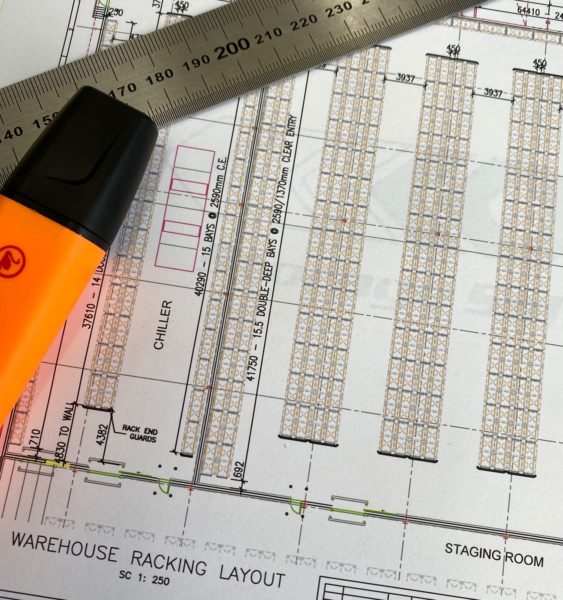

The first step in organizing your warehouse is to create a floor plan. This allows you to see where you want to store items, how many pallet spaces/pick faces you will be able to have, as well as any physical space limitations of the building itself. Putting plan to paper before you put it into practice helps you visualize the system in use, and be prepared for any obstacles that may arise.

The team at Colby Derrimut has years of experience working with clients from a variety of sectors. This enables us to help utilise your space for your specific purpose, optimising your warehouse and increasing warehouse productivity. Each client is provided with a detailed scale drawing of their warehouse and proposed storage system, ensuring that all obstacles are planned for and can be overcome prior to the installation going ahead.

Selecting Racking and Shelving Solutions

The most important part of setting up a warehouse is selecting the type of storage system you will implement. As there is a vast array of Racking and Shelving Types, it is important to select the type of racking that will best suit your business operations. For a large amount of SKU’s where full access is required to all pallets, a standard selective pallet racking system is ideal. If your business has high volume with a smaller amount of SKU’s – a Drive-In Racking system may give you the best optimisation of your space. Colby Derrimut can assist you in this selection process, as we offer a full range of racking products which are both Australian made and designed and tested to rigorous international standards.

Hand Pick Solutions and Accessories

If your warehouse involves hand picking operations, it is important to implement these in your storage space. Combining pick levels with pallet storage is a great way to implement hand pick locations if space is at a premium. Where in larger warehouses, isolated shelving bays can be installed for specific pick locations. Colby Derrimut have a wide range of Shelving systems to suit any products. We supply Australian made Delta Mesh Decks to suit any product, from lightweight goods to heavy duty workshop materials. We also can supply timber shelving or Workbenches for pick-packing operations. Colby designs and supplies their own Carton Live Storage system for a First-In, First-Out picking solution for a FMCG environment.

Colby Derrimut also supplies a range Australian made Plastic Fischer Storage Bins, Rack Identification Products and other organisation accessories to help optimise your space.

Pallet Racking Maintenance

Warehousing is one of the more dangerous work environments in Australia, so it is of upmost importance that businesses provide their employees with a safe place to carry out their work.

It is also required by Australian Standard 4084.2012 that a warehouse racking system is inspected for compliance issues and damage every 12 months. Colby Derrimut offers a service where you are contacted annually to book in a full site racking inspection. On completion of this you will be provided with a detailed report, site damage map and quotation to repair racking and bring it up to Australian Standards.